You’re thinking, “Safety regulations are a bore!” But let’s turn that around. You wouldn’t want to be caught in a construction mishap, would you? That’s where OSHA Standards come into play. They’re not just rules; they’re life-saving measures. So let’s dive in together and understand these guidelines better – because safety isn’t just about compliance, it’s your life on the line!

Understanding the Importance of OSHA Standards in Construction

It’s crucial to understand the importance of OSHA standards in construction as they’re designed to ensure worker safety and prevent accidents on job sites. These regulations aren’t just pieces of paper, they’re lifelines that can mean the difference between a normal day at work and a potentially fatal incident.

Workplace training is an integral part of these standards. You’re not only expected to know how to do your job but also how to do it safely. This involves learning about potential hazards, understanding how to handle equipment properly, and knowing what precautions should be taken in different situations. It’s more than just wearing a hard hat; it’s about making informed decisions that prioritize safety over speed or convenience.

Safety equipment plays a vital role too. From protective eyewear to high-visibility clothing, the right gear can significantly reduce risk factors. But remember, equipment is only as good as its maintenance – so make sure it’s always in top condition.

In essence, adhering to OSHA standards isn’t about ticking boxes or avoiding fines; it’s about safeguarding lives. Don’t underestimate their value – after all, you’ve got nothing if you haven’t got your health!

Diving Deep Into Specific OSHA Construction Safety Regulations

You’re about to delve into a comprehensive discussion on specific OSHA construction safety regulations that have been designed to ensure your well-being on the job site. We’ll dissect the critical aspects of Fall Protection Standards, uncover the integral elements of Hazard Communication Requirements, and navigate through Scaffold Safety Regulations. Equipped with this knowledge, you’ll be better prepared to identify potential hazards, take necessary precautions, and maintain an environment that prioritizes safety above all else.

Fall Protection Standards

OSHA’s fall protection standards are crucial because they are designed to prevent accidents and injuries on construction sites. These regulations mandate the use of Personal Protective Equipment (PPE) like harnesses, lanyards, lifelines, and anchors when you’re working at heights over 6 feet. Fall arrest systems are a significant part of these guidelines.

These safety measures ensure that if you slip or lose your balance, the fall arrest system will catch you before you hit the ground. It’s essential to comply with these regulations not just for legal reasons but also for your safety. Always remember: OSHA doesn’t just make rules; it creates safeguards to protect lives in hazardous work environments. So equip yourself properly and stay safe while performing high-rise tasks!

Hazard Communication Requirements

Understanding and adhering to hazard communication requirements is crucial, as they’re designed to ensure workers can identify and handle hazardous substances safely. It’s your responsibility to provide safety training that covers vital information about chemical hazards in the workplace. This includes understanding chemical labeling which should be clear, visible, and compliant with OSHA standards.

You must inform your team about the physical and health risks linked to chemicals present on-site. Teach them how to read Safety Data Sheets (SDS) for detailed information about each substance. The guidelines for using personal protective equipment when handling these substances should also be part of your training sessions.

Scaffold Safety Regulations

It’s crucial to be aware of scaffold safety regulations as they’re designed to protect workers from falls, injuries, and fatalities. Understanding Scaffold Erection Guidelines is vital for your team’s safety. It starts with ensuring the ground is firm and leveled before erecting the scaffold. The materials used must be robust, sound, and in good condition.

Next, familiarize yourself with Scaffold Inspection Procedures. These should take place before each work shift begins and after any event that could impact the structure’s stability. Inspections involve checking for visible defects, appropriate securing, correct bracing, and connections, etc.

Ignoring these procedures isn’t an option; it endangers lives. Your knowledge about these guidelines safeguards your team – don’t underestimate its importance.

The Role of OSHA in Reducing Construction Accidents

You’ll find that the role of OSHA in reducing construction accidents is crucial, as they implement safety standards and conduct regular inspections. They’re not just a regulatory body, but also an educator for companies and workers on their rights and responsibilities.

The effectiveness of OSHA training is evident in fewer incidents, improved compliance, and greater worker’s rights awareness. When you understand your rights as a construction worker under OSHA regulations, you’re more likely to assert them, leading to safer work environments.

Here are three ways OSHA reduces construction accidents:

1. Setting Standards: OSHA establishes comprehensive safety guidelines for various aspects of construction work – from scaffolding to electrical installations – ensuring you’re protected from potential hazards.

2. Regular Inspections: They don’t simply put rules in place and hope for the best. No, they conduct routine checks to ensure adherence to these standards.

3. Training Programs: This isn’t about making life difficult for businesses; it’s about saving lives. That’s why OSHA provides training programs promoting safe work practices.

Compliance Measures for the OSHA Standards in Construction

Complying with regulatory guidelines in the building industry is vital, not only to avoid penalties but also to ensure worker’s protection and well-being. You must understand that OSHA standards are designed for your safety, as well as that of your staff.

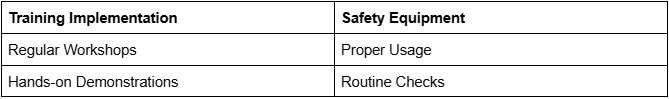

When it comes to training implementation, you need to provide comprehensive education on safety procedures and equipment use. This can be achieved through regular workshops or hands-on demonstrations. Remember, a well-trained workforce is less likely to make mistakes that could lead to accidents.

In terms of safety equipment, ensuring its proper use and maintenance is paramount. Regular checks should be conducted so you’re confident that everything is in top condition.

Here’s a simple table summarizing key compliance measures:

The Penalties for Non-Compliance With OSHA Construction Safety Standards

You’re about to delve into a critical discussion on the penalties associated with non-compliance of OSHA’s construction safety standards, particularly focusing on their severity. We’ll also scrutinize the dire consequences you’d face for repeat violations and how they can escalate if not properly addressed. Furthermore, we won’t leave you in the lurch – we’ll explore proactive strategies that you should employ to avoid these non-compliance penalties altogether.

Severity of Penalties

It’s important to understand that the severity of penalties can vary significantly depending on the nature and frequency of safety violations. Penalties aren’t random, they’re based on a well-defined set of rules and regulations.

1. Penalty Appeals: You have the right to contest any penalty if you believe it’s unjustified or too severe. Make sure to present solid evidence during your appeal.

2. Inspection Procedures: Regular inspections play a key role in determining penalties. The inspector will assess how often you’ve violated OSHA standards and how serious these violations are.

3. Severity of Violations: Often, repeated or severe violations lead to harsher penalties.

Always remember, maintaining safety is not just about avoiding fines; it’s about ensuring a safe environment for all workers on site.

Repeat Violation Consequences

Should you have multiple infractions, they’ll significantly increase your penalties, potentially leading to legal troubles or even the closure of your business. It’s essential to employ violation mitigation strategies promptly and effectively. Start by investing in thorough employee training programs that emphasize OSHA standards for construction safety. This won’t just reduce the risk of violations but also foster a safer work environment.

Remember, repeat violations indicate a disregard for safety regulations and can tarnish your company’s reputation. Your credibility with clients could be at stake too. Therefore, it’s crucial to rectify discrepancies swiftly and ensure they don’t recur.

In dealing with OSHA citations, proactive measures are always better than reactive ones. Keep safety a priority; it pays off in more ways than one!

Avoiding Non-Compliance Penalties

So, you’ve learned about the consequences of repeat violations. Let’s shift our focus to avoiding non-compliance penalties altogether. You have a responsibility to uphold workers’ rights and ensure safety training is top-notch.

1. Stay Knowledgeable: Familiarize yourself with OSHA standards regularly. They’re updated often and ignorance isn’t an excuse for non-compliance.

2. Safety Training: Invest in comprehensive safety training programs. This will not only keep your workers safe but also demonstrate your commitment to following regulations.

3. Workers’ Rights Awareness: Ensure every worker knows their rights under OSHA laws, such as the right to a safe workplace and the right to report unsafe conditions without fear of retaliation.

Case Studies: Impact of OSHA Standards on Construction Safety

We’ll delve into several case studies to examine the impact of OSHA standards on construction safety. You must understand how proper Safety Training and comprehensive Risk Assessment, following OSHA guidelines, can significantly reduce accidents and improve overall job site safety.

Consider these real-world examples:

In each case, adherence to OSHA standards proves beneficial. In Cases B & D, companies invested in proactive measures like enhanced training programs and meticulous risk assessments. Consequently, they experienced fewer accidents and regulatory violations compared to their counterparts in Cases A & C who neglected these important aspects.

This comparison clearly illustrates the positive impact of embracing OSHA’s recommended practices. You’re encouraged to incorporate such strategies into your operations not only for compliance but more importantly, for the well-being of your workforce.

Frequently Asked Questions

What Is the Process for Reporting a Violation of OSHA Standards?

When you spot a violation of OSHA standards, you report it directly to OSHA. You’re shielded by whistleblower protections, so there’s no fear of retaliation. Violation consequences can be severe, ensuring safety on site.

How Often Are OSHA Standards Updated or Revised?

OSHA standards aren’t updated on a set schedule. They evolve based on industry changes and compliance challenges. You must stay informed to ensure your worksite always meets the latest safety regulations.

How Can Construction Workers Receive Training on OSHA Standards?

You can access OSHA training through various online platforms or local institutions. They’ll guide you through the certification process, ensuring you’re well-versed in construction safety standards as per OSHA guidelines.

What Steps Should a Construction Company Take if It’s Unable to Meet a Particular OSHA Standard?

If you’re struggling with compliance challenges, don’t fret. You should identify standard alternatives and consult OSHA. They’ll help tailor a plan to meet safety regulations in an achievable manner for your construction company.

Are There Any Exceptions or Exemptions to OSHA Standards for Small Construction Businesses?

Yes, there are exceptions for small businesses facing OSHA compliance challenges. You can request consultation services to identify and correct potential hazards without fear of penalties or citations. It’s about safety, not size.

SEO done by datafanatics.com

To find more information related to OSHA standards and regulations, click here to view our blog list!